1. Location, Location, Location: What are New York Bricks?

The Hudson River from Staten Island to Kingston, NY was home to well over 120 brick manufacturing and distribution facilities during the 19th century. But why the Hudson? As luck would have it, the river's bed and banks contained deep and often soft clay deposits that had once comprised the bottom of glacial lakes from the last Ice Age. New York clay itself runs the gamut of mineral striations from pale grey to fiery red and there was certainly enough of it to provide both color consistency and variety during the City's buildings right through to the mid-20th century, when other materials such as concrete and glass became more popular. The terra cotta color we consider 'Brick Red' is seen throughout New York City, and The American Museum of Natural History certainly walks its talk by impressively reflecting this ancient coloring.

2. What's in a stamp (frog)?

The Hudson Valley brickyards were definitely the first great American brand marketers! It's almost impossible to find an unmarked antique New York brick because the foundry's name or mark was always molded into the face of every single piece it manufactured. Today, we can even discover a brick's provenance with the help of the 'Click-a-Brick' program at the Haverstraw Brick Museum(1). By 1882, the Haverstraw area alone had 42 brickyards with 188 distinct brands!(2).Although most people would argue that brick's recyclability, rather than its collectability is its best use, a single clearly marked antique brick in good condition has been known to sell for as much as $800.

3. Why did local brick become the cornerstone of New York City?

From the early 19th century's Schermerhorn Row to the mid 20th century's Stuyvesant Town, Hudson Valley bricks have been chosen by architects for their strength, light weight and impressive finished presentation. But the catalyst for brick's universal use was tragedy. Manhattan's Great Fires of 1835 and 1845 devastated entire blocks of wooden structures, which in turn precipitated a strict building code throughout the five boroughs. And since the code applied to businesses, residences, municipal buildings and institutions alike, it's easy to see how one legislative thrust resulted in a city built of brick.

4. When did brick making become New York's main industry?

The 'Long Century' that began with the French Revolution and ended with World War I saw at least 25 BILLION bricks manufactured and used, and that's just in Manhattan.(3) The popularity of elevators dictated higher buildings and stronger load bearing structures that required more bricks. When we count building booms in the other boroughs that busily kept pace, as did towns throughout the region, the number of billions of bricks produced can very safely be doubled! And it all had to be transported via an infrastructure that employed nearly every available hand in the City. So it's no wonder things got a little complicated; a fun brick secret is that NYC pier numbers don't correspond to NYC street numbers. For example, Pier 68 was a hub for Hudson River brick cargo going by rail to other destinations in the 5 boroughs, but it wasn't at 68th street. It was actually at 28th street and that railroad is now part of the High Line.

Hutton Brickyard, Kingston, NY. Picture courtesy of www.huttonbrickyards.com.

5. Who were New York's original Hudson River brick makers?

Richard Hutton, Peter de Noyelles and James Wood, who invented the quick-baking kiln, established brickyards between New York City and Kingston, 90 miles up-river from Manhattan. Other local founders whose names we still see on antique bricks include Robert Main of Saugerties, John Henry of Verplanck and Balthasar Kreischer of Staten Island. But there can be no 'Who's Who' of making bricks in New York without the workers who actually crafted them; immigrants fleeing either the Irish Potato Famine or other dire conditions across southern and eastern Europe, who were sometimes directly recruited from Ellis Island to the plants. The Hudson River brickyards promised a healthier lifestyle than the prospect of cramming an entire family into to one room in a Manhattan tenement but not everyone was lucky enough to be recruited. After the Civil War New York City's labor force was further strengthened by workers coming North during The Great Migration and by 1900 the brickmaking industry employed 1 out of every 8 people in Manhattan alone.

6. How were New York bricks made?

Before the Machine Age, bricks were laboriously poured into molds by hand and fired in small batches but in the early 1850s Richard Ver Valen introduced a steam powered engine for brickmaking. First used in Haverstraw, NY, Ver Valen's invention changed the brickmaking industry practically overnight. Some of the machine's many appeals were that less preparation of the raw material was needed, it could mass produce bricks from stiffer clay that guaranteed a more evenly shaped result and it had a labor-saving chain and bucket elevator. The new mass-molded bricks were then air dried and baked in huge coal-fueled kiln chambers for seven days at temperatures reaching 1,800 degrees Fahrenheit!

7. Speaking of weather, are bricks environmentally friendly?

Yes! Reused ones especially so, although a hundred years ago perhaps not so much. As the brickyards grew and became powered by coal instead of horses, a single plant could burn 100 tons of coal per million bricks; coal brought up-river by the same barges that transported the bricks back down to the city. Of course industry is not as beautiful as nature, but the general opinion was that brick was far more sustainable in a burgeoning metropolis such as New York than the smoke and destruction from the fires that constantly erupted in wooden structures. And the beauty of New York brick as a 19th century fireproof architectural component is that bricks made well over a century ago, often bearing fascinating provenance, are now recycled and proudly re-used in new as well as restoration construction projects throughout the New York area.

8. The great Dutch brick debate:

Legend has it that the original bricks to arrive in New Amsterdam doubled as ballast for the Dutch ships that carried them. It may well be true that imported brick was better-made than the rustic first efforts of 17th century Hudson River brickmakers and certainly, some of the oldest buildings we see depicted in histories of New Amsterdam are built in the Dutch style. One theory is that the Dutch brick, being of sentimental value, was saved for decor on facades, while chimneys and sidings were built from locally made brick. It is a fact, however, that Dutch brickmakers emigrated to New Amsterdam and that their expertise was germane to local brick becoming the cornerstone of that city - as well as of its later incarnation, New York.

9. Financial facts about New York brick:

In mid 19th century Manhattan, bricks cost a penny apiece, while records at The Haverstraw Museum show that women and children earned $2.00 and $1.25 a day respectively preparing them to dry by knocking excess clay of them one at a time. Logic tells us they earned less than the sale price, and research reveals a worker was likely expected to handle thousands of bricks per day. Even at 1,500 bricks daily, women earned .001 cent per brick. The men did more physical and dangerous labor but it was still considered unskilled so it earned them very little more and without unions, brickmakers' wages barely increased throughout the century. However, most brickyards did offer subsidized company housing. The Rose Brick Company built an entire town, Roseton, complete with a school and churches for its employees, although it lacked plumbing. But brickmaking was seasonal and when the Hudson River froze over so did its mud. Workers had to seek other jobs, such as harvesting its ice, but took comfort in brick homes that had coal burning stoves for the winter months and the security of knowing they were fireproof!

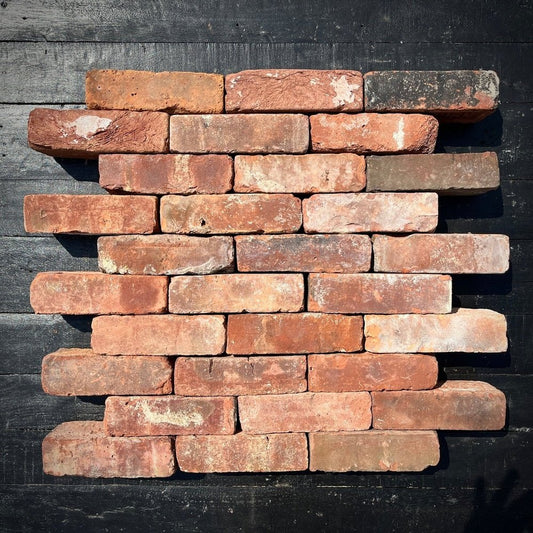

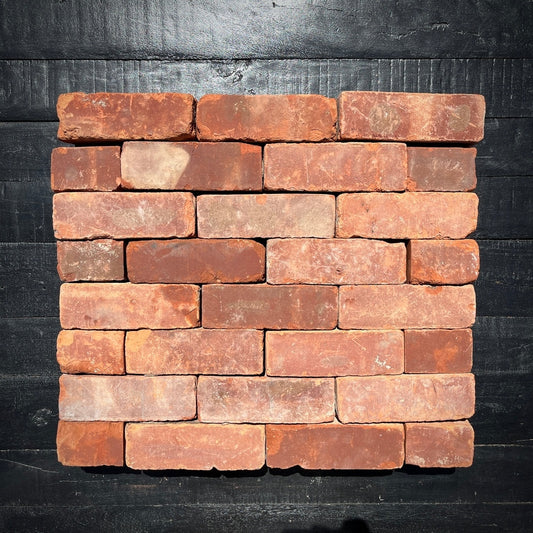

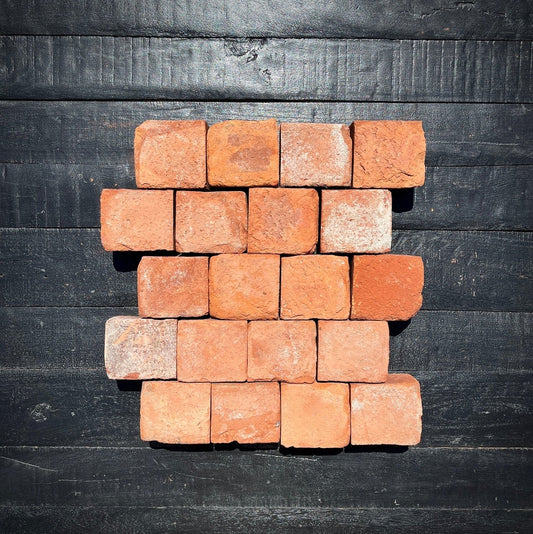

10. How is New York brick reclaimed and used today?

There's a meticulous process in place for the recovery of intact reclaimed bricks. Buildings awaiting demolition are carefully disassembled brick by brick and the blocks are manually cleaned and stored for transport on pallets to reclaimed building material suppliers who purchase them for resale. Clients at Chief Bricks use reclaimed brick for paving projects such as terraces or pathways, repairs on existing features whose colors can be matched for authenticity, and the creation of rustic-looking new additions to their properties. Historical Societies also often require that reclaimed bricks be used. The visual benefits are rewarding, the narrative of the brick's provenance is instantly beguiling, and the maintenance of their classic look would be impossible to imitate with new materials. But putting aesthetics and what we've just read aside, let's look at the ecological benefits of reusing New York bricks and rejoice in the fact that recycling brick is literally cleaning and re-using the earth.

#

(1) https://www.haverstrawbrickmuseum.org

(2) https://www.gothamcenter.org/blog/notes-on-manhattan-bricks

(3) https://www.livingplaces.com/NY/Rockland_County/Haverstraw_Town.html.