Granite steps, precast concrete steps, and wood steps can all create a usable entry, but they perform very differently over 20–40 years when you factor in durability, maintenance, and replacement cycles.

Granite generally has the highest upfront cost but the lowest long‑term risk, precast concrete sits in the middle, and wood is usually cheapest at first but can become the most expensive over time once ongoing maintenance and replacements are included.

Material Overview

Each step material has a different structure, strengths, and weaknesses that affect how it performs at your home’s entry.

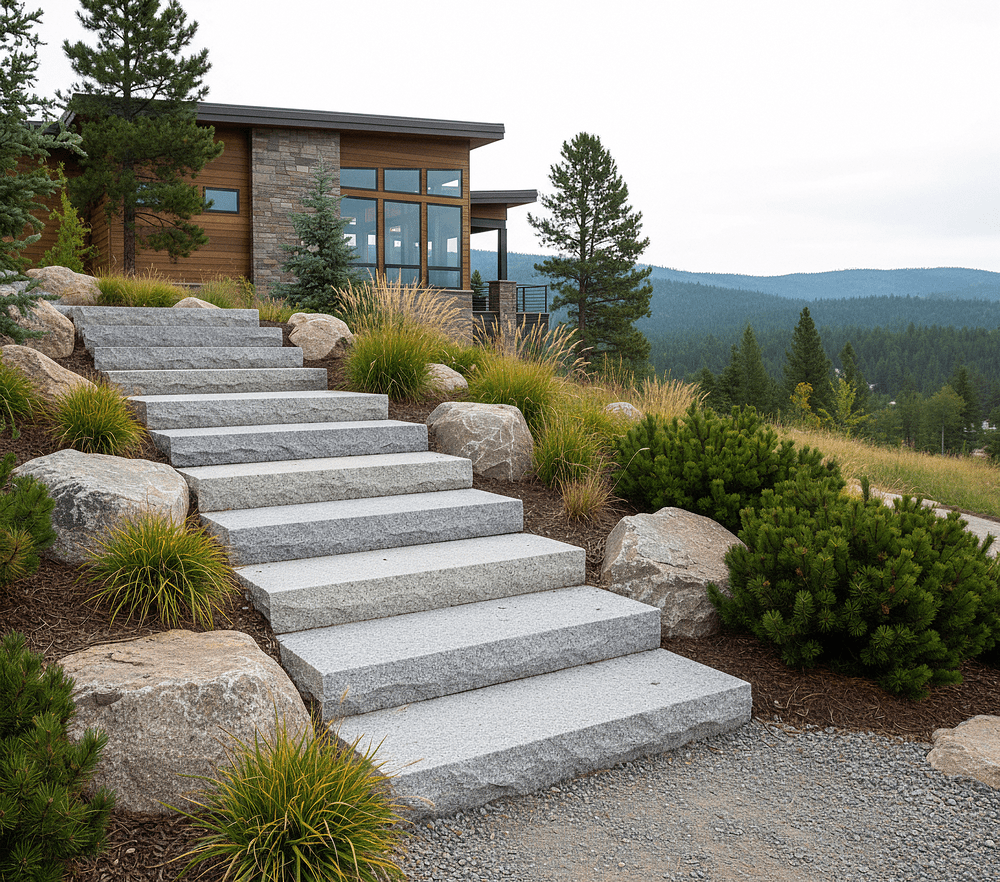

Granite Steps

Granite steps are solid blocks of natural stone, often around 7 inches thick, with a flamed or thermal non‑slip top and a rock‑faced or eased front edge. They routinely reach compressive strengths roughly four to five times higher than typical concrete and can outlast multiple generations with minimal maintenance.

Precast Concrete Steps

Precast concrete steps are factory‑made, usually hollow units that are craned into place onto a small footing or pad, offering consistent quality, quick installation, and solid performance compared with many cast‑in‑place or site‑built alternatives.

Wood Steps

Wood steps are typically built from pressure‑treated framing and decking boards on site, with the lowest initial cost but a higher vulnerability to rot, warping, and surface wear in exposed outdoor conditions.

Summary

| Aspect | Granite Steps | Precast Concrete Steps | Wood Steps |

|---|---|---|---|

| Basic construction | Solid natural stone blocks with thermal top and finished nose. | Factory‑cast, often hollow concrete units craned into place. | Site‑built frames with wood treads and risers. |

| Typical compressive strength | Very high (stone used in bridges/plazas). | Moderate, around typical structural concrete ranges. | Not rated like concrete; strength depends on lumber size and species. |

| Typical use | Premium entries and long‑term projects. | Standard residential and light commercial steps. | Porches, decks, and budget‑driven projects. |

| Upfront cost tier | Highest. | Mid‑range. | Lowest. |

| Typical installer | Masons, stone or hardscape contractors. | Concrete and precast suppliers/contractors. | General contractors, carpenters, some DIY. |

Durability and Performance Over Time

Long‑term durability determines how often you will repair or replace your steps and how they will look after years of weather and use.

Granite

Granite’s high compressive strength and dense structure allow it to resist chipping, cracking, and structural failure under normal residential loads, and it is not damaged by UV or internal steel corrosion. It handles freeze‑thaw cycles and de‑icing salts with very little visible change over decades when properly installed.

Precast Concrete

Precast concrete is much more durable than many site‑poured or wood options, but over time it can develop hairline cracks, scaling, and spalling, especially in climates with aggressive freeze‑thaw and de‑icing chemicals. Hollow interiors and thin sections are particularly susceptible if drainage is poor or supports shift.

Wood

Even treated wood eventually suffers from rot, fungal decay, insect attack, and warping when repeatedly exposed to moisture, sun, and snow, making long‑term structural integrity more uncertain than stone or concrete.

Summary

| Aspect | Granite Steps | Precast Concrete Steps | Wood Steps |

|---|---|---|---|

| Resistance to cracking | Excellent; very low crack risk when properly supported. | Moderate; hairline and structural cracks possible over time. | Boards split or check as they weather. |

| Freeze‑thaw performance | Very good, even in cold climates. | Good, but vulnerable to spalling and scaling. | Moisture cycling accelerates decay and warping. |

| Salt and chemical exposure | Handles de‑icers better than concrete. | De‑icers can pit and weaken the surface. | De‑icers and moisture degrade finishes faster. |

| Expected structural lifespan | Multi‑decade to generational with good base. | Often 15–25+ years in harsh climates. | Commonly 10–20 years before major rebuilds. |

| Long‑term appearance | Develops patina but stays visually strong. | Cracks and stains tend to show over time. | Finishes fade, boards weather and warp. |

Safety, Comfort, and User Experience

Safety and comfort are critical for everyday use, especially in wet or icy conditions and for households with children or older adults.

Granite

Granite steps typically feature thermal or flamed tops that provide a textured, non‑slip surface underfoot, making them well suited to rainy or snowy climates. Their solid mass eliminates bounce, and edge profiles can be chosen for both style and safety, including eased or rounded noses.

Precast Concrete

Precast concrete can be broom‑finished or textured for better traction, but surfaces may become slick when worn or if algae grows, requiring occasional cleaning to stay safe. Stability largely depends on proper support; shifting foundations can create uneven risers or rocking that affect safety.

Wood

Wood offers some natural grip when new, but finishes wear off and surfaces can become slippery when wet or algae‑covered, especially in shade. Flex or bounce in older wood stairs and loosening fasteners can affect confidence and comfort over time.

Summary

| Aspect | Granite Steps | Precast Concrete Steps | Wood Steps |

|---|---|---|---|

| Slip resistance | Thermal/flamed tops, high traction when maintained. | Can be textured, may become slick if dirty or worn. | Initially good, degrades with weather and algae. |

| Structural feel underfoot | Very solid, no bounce. | Solid when well supported; can rock if base shifts. | May flex or bounce depending on framing. |

| Edge profile options | Rock‑faced, eased, or rounded noses available. | Mostly simple cast edge shapes. | Cut or routed nosings; can splinter. |

| Performance in ice and snow | Very good with proper snow removal. | Good if textured, can polish or glaze over time. | Highly dependent on finish and maintenance. |

| Typical maintenance for safety | Occasional cleaning to keep surface clear. | Cleaning and occasional crack/spall repairs. | Frequent cleaning, refinishing, and board checks. |

Maintenance Requirements

Maintenance has a major impact on total ownership cost and the time you spend keeping steps safe, clean, and attractive.

Granite

Granite usually needs only basic sweeping and occasional rinsing, with no regular sealing or painting required in most exterior residential applications. Periodic checks for base movement or drainage problems are typically all that is needed.

Precast Concrete

Precast steps benefit from periodic cleaning, monitoring for cracks or spalls, and maintenance of caulking or joints where the unit meets the house or adjacent slabs.

Wood

Wood requires the most attention, including regular staining or painting, replacement of damaged boards, and tightening or replacing corroded fasteners to keep the stair safe and attractive.

Summary

| Aspect | Granite Steps | Precast Concrete Steps | Wood Steps |

|---|---|---|---|

| Routine cleaning | Sweep and rinse as needed. | Wash to remove dirt, algae, and stains. | Clean plus more frequent debris removal to protect finishes. |

| Protective coatings | Usually none required outdoors. | Optional sealers for stain and freeze‑thaw protection. | Regular stain/paint or water repellents required. |

| Repairs | Rare; occasional resetting if base settles. | Crack and spall repairs plus joint maintenance. | Board replacement and fastener repairs common. |

| Inspection frequency | Low; seasonal visual checks. | Moderate; periodic evaluation for cracking and movement. | High; regular checks for rot, loose boards, and safety issues. |

| Owner time commitment | Minimal. | Moderate. | High over the life of the stairs. |

Lifetime Cost and Replacement Cycles

Upfront price is only part of the story; replacements, repairs, and maintenance over 20–40 years often change which option is truly cheapest.

Granite

Granite has the highest initial material and installation cost, but it can easily serve for 40–50 years or more with minimal maintenance and no structural replacement, making its long‑term cost surprisingly competitive.

Precast Concrete

Precast concrete typically costs more than wood but significantly less than granite up front, with many installations needing significant repair or replacement in roughly 15–25 years in harsh climates.

Wood

Wood usually offers the lowest upfront cost but the shortest service life, with frequent maintenance and likely complete replacement at least once or twice over a 30‑year period, driving lifetime costs up.

Summary

| Aspect | Granite Steps | Precast Concrete Steps | Wood Steps |

|---|---|---|---|

| Typical upfront cost tier | High. | Medium. | Low. |

| Expected replacement cycle | Rare; may never need full replacement. | Often 15–25+ years. | Commonly 10–20 years. |

| Maintenance cost over time | Very low. | Moderate (repairs plus cleaning). | High (finishes, repairs, rebuilds). |

| 30‑year total cost tendency | Often best value despite high initial cost. | Mid‑range, including at least one repair or replacement. | Can exceed alternatives due to multiple rebuilds. |

| Best fit buyer | Long‑term owners prioritizing durability and curb appeal. | Value‑oriented buyers needing quick, durable solutions. | Budget‑focused buyers or temporary solutions. |

Share:

Granite Steps: The Complete Homeowner Guide to Beautiful, Long‑Lasting Front Entries

Granite Steps vs Granite Treads: Which Is Right for Your Entry?