Using Chief Bricks' reclaimed bricks and cobblestones to boost your project's certification with LEED v4 & v5 sounds like a mouthful, but it points to something simple. You want beautiful, durable hardscape materials that also help you score real sustainability points. You also want to know that all those credits translate into higher value and lower risk.

If you are an architect, builder, homeowner, or landscape designer, you are likely balancing two pressures. One is the push to cut embodied carbon, waste, and costs. The other is the demand to create spaces that feel warm and timeless.

LEED v4 & v5: Using Chief Bricks' Reclaimed Bricks and Cobblestones to Boost Your Project's Certification can sit right in that overlap. This is where high-quality reclaimed materials shine. Reclaimed brick and cobblestone, and Belgian block take care of a huge part of the story.

You are reusing durable materials that have already proved themselves in service. This matches exactly where LEED v4 and the upcoming LEED v5 are heading. They focus on raw material credits and the zero waste hierarchy described by the Zero Waste International Alliance at zero waste hierarchy.

Table of Contents:

- Why Reuse Is Moving To Center Stage In LEED v4 And LEED v5

- How LEED v4 & v5: Using Chief Bricks' Reclaimed Bricks and Cobblestones to Boost Your Project's Certification Actually Works

- Detailed Credit Achievement Calculation For Reused Materials

- Where Reclaimed Bricks And Cobblestones Can Earn Credits

- Navigating Material Categories: What Reclaimed Masonry Is Not

- Quick Comparison Of LEED v4 And LEED v5 Material Reuse Focus

- Why Reclaimed Brick And Cobblestone Hit LEED And Market Goals At The Same Time

- Design Possibilities Architects And Landscapers Love

- Documenting Reclaimed Materials For LEED v4 And LEED v5

- Integration With Producer Responsibility and Stewardship

- Why LEED v5 Is Good News For Reclaimed Brick Lovers

- Bringing Story And Heritage Into Your Project With Historic Bricks

- Technical Validation: Testing Reclaimed Materials

- Making Reclaimed Brick Work For Homeowners And Small Builders

- Learning More About Hardscape Design With Reclaimed Products

- Practical Steps To Use Reclaimed Masonry On Your Next LEED Project

- Why Now Is A Smart Time To Lean Into Reclaimed Bricks And Cobblestones

- Conclusion

Why Reuse Is Moving To Center Stage In LEED v4 And LEED v5

For years, projects relied on recycled content and improved manufacturing as their main material strategy. LEED v4 kept some of that approach. However, it started to push project teams toward reuse and life cycle thinking.

With LEED v5, that push becomes stronger. The system now highlights circular economy ideas. It rewards source separation and material reuse.

The rating system pulls back on lower impact moves like mixed recycling. That shift puts reclaimed masonry and stone in a very strong position for leed project types including BD+C and site heavy work. The USGBC describes LEED v5 as built around three big impact areas.

These areas are decarbonization, health, and resilience. You can see that direction reflected in the new LEED v5 Reference Guide. This was announced at events like the Greenbuild International Conference and Expo.

How LEED v4 & v5: Using Chief Bricks' Reclaimed Bricks and Cobblestones to Boost Your Project's Certification Actually Works

You might be thinking that all sounds nice in theory, but you need to know where the points come from. Under LEED v4 and v4.1 for Building Design and Construction, reclaimed brick plugs straight into Sourcing of Raw Materials. This is specifically under the materials reuse option.

This option awards points based on the cost of permanently installed reused materials. This is calculated compared to the total permanently installed building products cost. LEED v4 typically gives 1 point when you hit 25 percent of materials by cost.

You can gain 2 points if you reach 50 percent. Materials reuse is one of the primary pathways to reach those thresholds. This contributes directly to your leed certification goals.

LEED v5 follows the same spirit with its Materials Reuse option under Sourcing of Raw Materials. LEED v5 strengthens that stance because reuse now sits in a higher tier. It matches the focus on the zero waste hierarchy from ZWIA.

Detailed Credit Achievement Calculation For Reused Materials

Understanding the math is vital for your credit achievement calculation. When you select products, you must aggregate the cost of all permanently installed building items. You then separate the value of the reused content.

For a leed credit, the cost of the reclaimed brick or stone counts 100% toward the numerator. This differs from postconsumer recycled content which might be weighted differently. To verify the credit achievement, you need accurate receipts.

Your achievement calculation relies on proving the material was previously used. It does not require a complex environmental product declaration. This simplifies the process compared to sourcing new items with an environmental product label.

Where Reclaimed Bricks And Cobblestones Can Earn Credits

You can use reclaimed brick and stone almost anywhere masonry or pavers are called for. That gives you flexibility as a designer or homeowner. This versatility applies to exterior landscapes and interior design elements alike.

Here are typical locations where those products can count as reused materials for LEED purposes.

- Exterior walls, garden walls, and retaining walls

- Plazas, courtyards, and walkways

- Driveways, alleys, and service yards

- Patios, pool decks, and outdoor rooms

- Raised beds and edging in landscape work

If they are part of the final built work and permanently installed, you can usually claim their value. You simply include them in the materials cost totals. The key is to treat them as a normal specification.

Navigating Material Categories: What Reclaimed Masonry Is Not

It is helpful to understand what categories you avoid by choosing reclaimed stone. You do not need to worry about the strict criteria for bio-based products. When dealing with bio-based items, you often have to check extraction criteria.

Furthermore, masonry is simpler than sourcing leather or hides for interiors. LEED guidelines often require teams to exclude hide products or specific animal skin material from certain bio-based calculations. There is no need to exclude hide components when using brick.

You also avoid the chain of custody paperwork required for wood products. While forest stewardship council certification is great for lumber, reclaimed masonry is simpler. It inherently meets the goal of resource preservation without needing a stewardship council certificate.

Quick Comparison Of LEED v4 And LEED v5 Material Reuse Focus

To help you understand the changes, this table outlines the shift in focus. It highlights how the leed credit library is evolving. Refer to the language guide addenda resources for official updates.

| Item | LEED v4 / v4.1 | LEED v5 |

|---|---|---|

| Main credit name | Sourcing of Raw Materials | Sourcing of Raw Materials |

| Reuse role | One of several compliant strategies | Higher emphasis as a top tier strategy |

| Zero waste link | Implied through source reduction | Clear tie to circularity and zero waste hierarchy |

| Recycled vs reused | Balanced | Reuse moves ahead of mixed recycling |

Checking the guide addenda regularly ensures you have the latest rules. The addenda resources can clarify specific reuse situations. This keeps your documentation airtight.

Why Reclaimed Brick And Cobblestone Hit LEED And Market Goals At The Same Time

You do not specify reused materials only for points. There is also the real estate side. The USGBC often highlights that a certified building product contributes to higher asset value.

Research from firms like Cushman and Wakefield covers this in their green building series. Now think about the buyer or tenant tour. Walking up to a drive lined with reclaimed cobblestones tells a story.

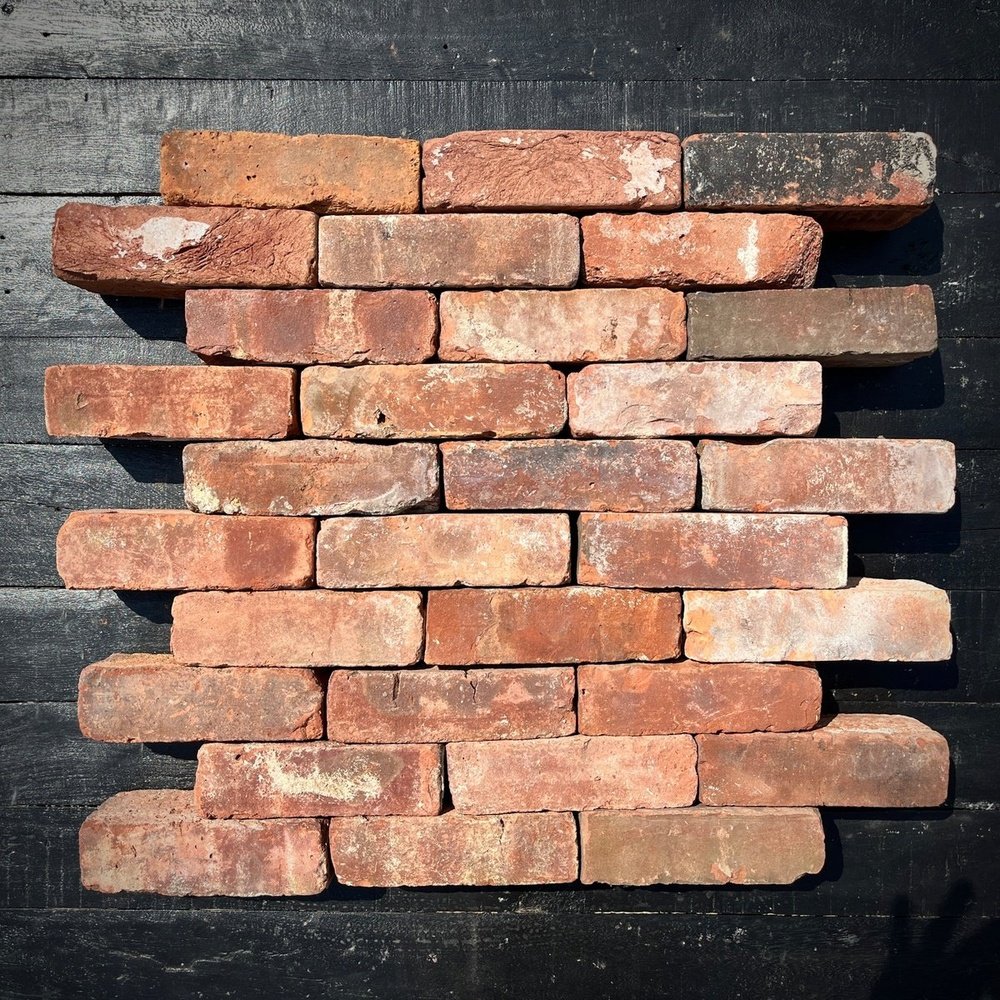

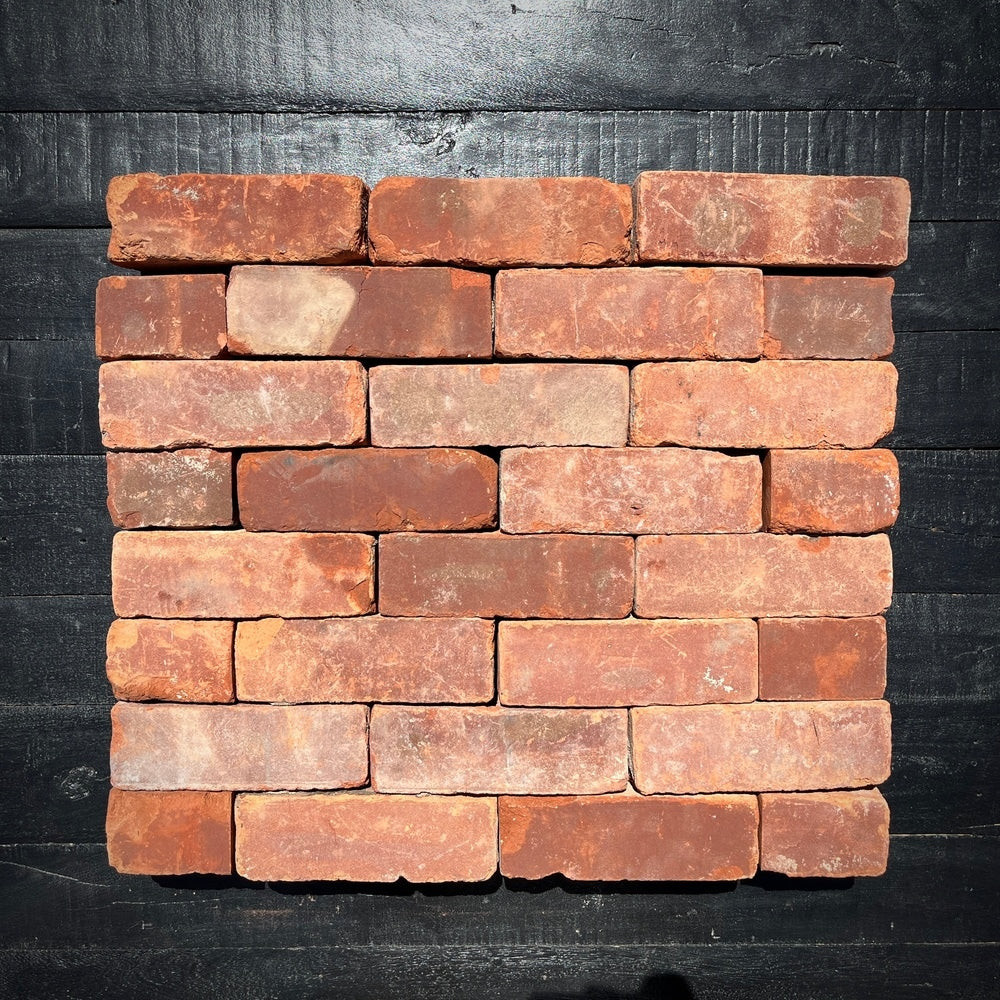

Those pavers or bricks show age and depth that fresh material cannot fake. That emotional weight becomes part of the premium. It signals quality beyond just an energy star rating on an appliance.

There is also risk and durability. Reclaimed brick or stone from streets has taken decades of abuse. Using these pieces feels conservative because you know they last.

Design Possibilities Architects And Landscapers Love

If you design or build outdoor space, you have probably seen various courses. One popular example is Using Reclaimed Materials in Hardscape Projects from the American Society of Landscape Architects. It walks through layout patterns and load bearing considerations.

Reclaimed bricks and Belgian blocks add even more options on your boards. Because the modules are fixed by their original manufacture, you can blend modern restraint with historic scale. This is a clear alternative to standard installed building products.

On a small backyard project, that might be a herringbone terrace. On a multifamily podium deck, it could be long ribbons of cobbles. The same units flex to fit a lot of styles.

Documenting Reclaimed Materials For LEED v4 And LEED v5

Reused products are not hard to document, but you need a simple system. Many teams still walk sites with clipboards and printed checklists. Others lean on digital tools to track diverted materials.

Apps like Green Badger can support LEED documentation. They let teams attach photos, notes, and quantities in the field. This helps organize your resource library.

For reclaimed bricks and cobblestones, there are a few pieces you will want in your folder. These items prove the products meet criteria for reuse.

- A supplier letter or cut sheet stating the material is reclaimed and from prior use

- Quantity and cost by line item for those units

- Photos or records of the original source stock if possible

- Layout plans or schedules that match the LEED calculator lines

If your LEED manager can open a single folder and see cost and proof, you are in good shape. You can then plug the numbers straight into your Materials Reuse option. This works for both v4 and v5.

Integration With Producer Responsibility and Stewardship

LEED v5 places heavy emphasis on where things come from. This often involves an extended producer responsibility program. New products often require a formal responsibility program to manage their end of life.

Reclaimed materials naturally bypass the need for a new producer responsibility plan. The material is already being saved from the landfill. This act of waste diversion is the ultimate form of stewardship.

It acts as a usgbc-approved equivalent to many take-back programs. You are extending the life of the product directly. This aligns with the concept of extended producer responsibility without the administrative burden.

Why LEED v5 Is Good News For Reclaimed Brick Lovers

The USGBC has now opened certification to LEED v5. They have shared updated tools and guides to make the switch easier. The product manufacturer community is adapting quickly.

The message is pretty clear. Projects that decarbonize, manage waste wisely, and care for occupant health will stand out. Reuse shows up in all those themes.

Heavy masonry reuse hits embodied carbon and waste reduction at the same time. This strategy helps reward project teams who think long-term. It aligns with the forest stewardship ethos of preserving resources.

USGBC reports that more than 20 early projects in the Operations and Maintenance path have already gained certification. Many report real savings and strong occupant feedback. That kind of traction sends a signal.

Bringing Story And Heritage Into Your Project With Historic Bricks

There is also a cultural side that is easy to overlook during calculations. Historic bricks often come stamped or colored in unique ways. This hints at the places they came from.

There is an entire hobby field around them. Sites such as chiefbricks.com show this interest. Spaces that lean into that heritage carry deeper meaning.

For some clients, seeing that their garden path is paved with brick styles documented in collections is a bonus. The Haverstraw Brick Museum showcases many of these styles. It becomes a talking point about preservation.

You can pitch reused masonry in more than one way. You can lead with performance or history. The right blend depends on whether your audience cares more about payback or story.

Technical Validation: Testing Reclaimed Materials

Some engineers worry about the structural integrity of old materials. It is common to ask if products purchased second-hand are safe. You can verify this using a standard test method.

Bricks can be subjected to an astm test method on a sample for compressive strength and absorption. An astm test ensures the material meets current codes. This validation removes the guesswork.

Once validated, these items are fully capable installed building products. They often exceed modern standards for density. This makes them a socially preferable option due to their longevity.

Making Reclaimed Brick Work For Homeowners And Small Builders

If you are working on custom homes or smaller jobs, LEED might feel far away. You may care more about basic payback and curb appeal. Reclaimed brick and cobblestone can still earn their spot here.

The main questions owners tend to ask are simple. Will this last? Will it look good in ten years?

How hard is it to keep clean? On those points, dense old bricks and granite cobbles usually do well. They resist chips and fade gracefully.

You can also speak to resale. Buyers who are learning about sustainability recognize reclaimed surfaces as a signal. They are becoming used to green labels through groups such as the Center for Green Schools.

Media about LEED and WELL also drives this awareness. Old masonry tells them the project has been planned with care. This can help reward project investment at the time of sale.

Learning More About Hardscape Design With Reclaimed Products

If you want to sharpen your design skills in this space, there are a few great paths. The American Society of Landscape Architects has many courses on exterior work. This includes the session on reclaimed materials from their online catalog at Using Reclaimed Materials in Hardscape Projects.

For broader professional development, ASLA's Online Professional Education series is excellent. It ties hardscape design to health, safety, and welfare needs. Those ideas line up closely with how LEED v5 is crossing over with systems like WELL.

You can see this alignment in tools like the LEED v5 and WELL crosswalk. There is also the LEED v5 and SITES crosswalk. That crossover matters significantly.

If your reclaimed brick plaza can help a client in multiple frameworks at once, it becomes an easier sell. The resources credits line up and your design work goes further. This maximizes the utility of building products selected.

Practical Steps To Use Reclaimed Masonry On Your Next LEED Project

You might be ready to try this on a live job, but wondering what to do first. A simple way to think about it is as a short checklist. This helps regarding demolition waste management and sourcing.

- Pick at least one strong candidate use, such as a plaza or drive.

- Confirm structural and frost requirements, so reclaimed units meet performance needs.

- Get budget pricing and lead time early from a supplier.

- Ask for documentation that clearly labels the product as reclaimed from prior use.

- Work with your LEED consultant to assign those costs to Materials Reuse.

- Track installation photos and receipts to make submittals easier later.

If that sounds straightforward, that is the point. You are not adding a brand new system. You are changing the source of a familiar material class.

This approach also helps with your diversion rate goals if you are demolishing existing structures. Integrating these steps improves your overall language guide addenda compliance strategy.

Why Now Is A Smart Time To Lean Into Reclaimed Bricks And Cobblestones

The momentum behind reuse will likely grow as more projects register under LEED v5. The USGBC is making it clear that materials that prevent waste will carry weight. They are backing that with fresh guides.

These are collected under their LEED v5 Reference Guides. Meanwhile, investors and tenants are tracking ESG performance. Research from groups like Cushman and Wakefield keeps drawing the same connection.

Thoughtful green upgrades tend to boost building value. They describe this phenomenon at Green is Good. Specifying reclaimed brick and cobblestone is less of a niche move now.

It is becoming part of sound practice for both technical teams and market focused owners. It keeps you in step with LEED v4 today. It also places you well for LEED v5 over the coming decade.

The strategy of selecting products with history is gaining traction. It serves as a model for extended producer logic. It simplifies how we define a sustainable building product.

Conclusion

You have a lot of choices for site materials, and it is easy to fall back on standard catalog options. Those options often do nothing special for your scorecard. But if you look at how LEED v4 and the newer v5 system treat reuse, a different path opens up.

By choosing reclaimed brick, cobblestone, and Belgian block, you respond directly to the credit language in Sourcing of Raw Materials. You align with the zero waste hierarchy that LEED v5 has embraced. You create warmer spaces that clients notice.

This choice allows you to back up aesthetics with real recycled content criteria performance data. And as LEED v4 & v5: Using Chief Bricks' Reclaimed Bricks and Cobblestones to Boost Your Project's Certification continues to guide teams, strategies like this will gain value. You are helping your project tell a better story on day one.

Ultimately, checking the guide addenda resources and selecting reclaimed options simplifies your path to certification. It avoids complex content criteria hurdles found in other categories. It is a smart, actionable way to build better.

About the author

Alkis Valentin is the founder of Chief Bricks and a specialist in reclaimed brick, cobblestone, and natural stone for high-end residential and landscape projects nationwide.

Share:

Designing Your Dream Home with a Natural Stone Staircase

Granite Steps vs. Concrete Steps: Which Is Better for Your Project?